Ink dispensing – where base colours, varnishes and additives are automatically mixed in exact quantities – has transformed colour management for packaging and label printers. Replacing time-consuming, error-prone manual mixing, it has enabled the availability of accurate colours, on-demand, without waste.

In a previous blog, we explained the difference between volumetric and gravimetric ink dispensing methods – and why gravimetric dispensing has become the industry standard for spot colour formulation.

In this follow-up, we take a deeper dive into the technology behind gravimetric dispensing.

More than just a scale and a pump, modern ink dispensing is powered by a smart combination of hardware and software – working together to ensure precision and repeatability. We explore the building blocks of these systems, and how they help printers meet the brand owners’ needs for consistent colour accuracy across different substrates – while supporting a sustainable, efficient and agile workflow.

The ink dispensing process

The automated ink dispensing process begins when a colour formula is selected within the ink management software. This formula defines the individual ink components and the quantities required to produce the desired colour. Once the job starts, the system precisely coordinates pumps, valves, and the weighing scale to dispense each component sequentially, ensuring the correct amount is added before moving to the next. This step-by-step dosing guarantees both accuracy and consistency, while preventing cross-contamination.

To achieve both speed and precision, each ingredient is typically dispensed in three flow stages:

- Coarse flow rapidly delivers most of the required amount to save time.

- Fine flow slows the rate as the target weight nears, improving control and reducing the risk of overshooting.

- The drip phase makes final, precise adjustments, ensuring the dispensed amount is as close to the target as technically possible.

This animation demonstrates the dispensing process of two ingredients in action, beginning with a coarse flow and then transitioning to a fine flow to achieve a precise final weight.

To understand how these stages are executed automatically, we can look at how the system coordinates its hardware and software components.

How automated ink dispensing works

Modern ink dispensing technology relies on a coordinated sequence of software control, automation hardware and precision measurement, to ensure accurate and repeatable formulations.

The process begins when a formula is selected in an ink management software programme, which sends structured, formula specific dosing instructions to the controller. This can be either a programmable logic controller (PLC) or a real-time controller (RTC). The controller then activates the appropriate pumps and valves to deliver each ink component, managing both coarse flow and fine flow dosing paths.

To execute these flow stages, the system relies on multistage dispensing valves, where both coarse and fine flow are controlled by adjusting the valve opening – typically via pneumatically actuated pistons. The pumps are either pneumatically or electrically driven, with the controller dynamically adjusting pump speed throughout the different dosing phases to match the required flow rate.

As ink enters the container, a high resolution weighing scale feeds real time weight data back to the controller, allowing it to adjust pump speeds and valve timing with millisecond accuracy.

The feedback loop: automated corrections to ensure accuracy

Accuracy in ink dispensing is achieved through this continuous feedback loop that monitors and corrects the process in real time. At the heart of this loop is the weighing scale, which verifies that each ink component is dispensed according to the defined formula.

During dispensing, the system continuously compares the measured weight to the target weight. When the target is reached within the specified tolerance, typically between 1 g and 0.01 g, the system confirms the result and proceeds with the next ingredient. This verification step ensures that each component is dispensed in the correct proportion, according to the original ink formulation.

If an overshoot is detected, the system does not rely on manual intervention. Instead, it automatically initiates a correction process. Based on the measured deviation, the dispensing software recalculates the required adjustments and compensates by adding controlled amounts of the relevant ink ingredients. By adjusting the formulation in a calculated and consistent manner, the system brings the mixture back within specification to maintain colour accuracy. This automatic feedback and correction mechanism is essential for reliable, repeatable results.

Ink dispensing technology at GSE

At GSE, modern ink dispensing technology is central to how ink is delivered fast, accurately, and repeatably for colour production. Our GSE Ink manager user interface (UI) software in combination with our real-time machine controls software makes full use of advances in automated dosing, combining precise pump control, intelligent valve strategies, and real time measurement to achieve both speed and consistency.

By integrating seamlessly with GSE Ink manager, the real-time controller receives structured, formula specific dosing instructions, ensuring each component is executed in the correct sequence. The UI software, controller, pumps, valves, and weighing scale operate as a unified system, enabling smooth transitions between the coarse flow, fine flow, and drip phases. This allows the dispenser to move quickly through the bulk of each component while maintaining tight accuracy as the target weight is approached.

Artificial intelligence in action

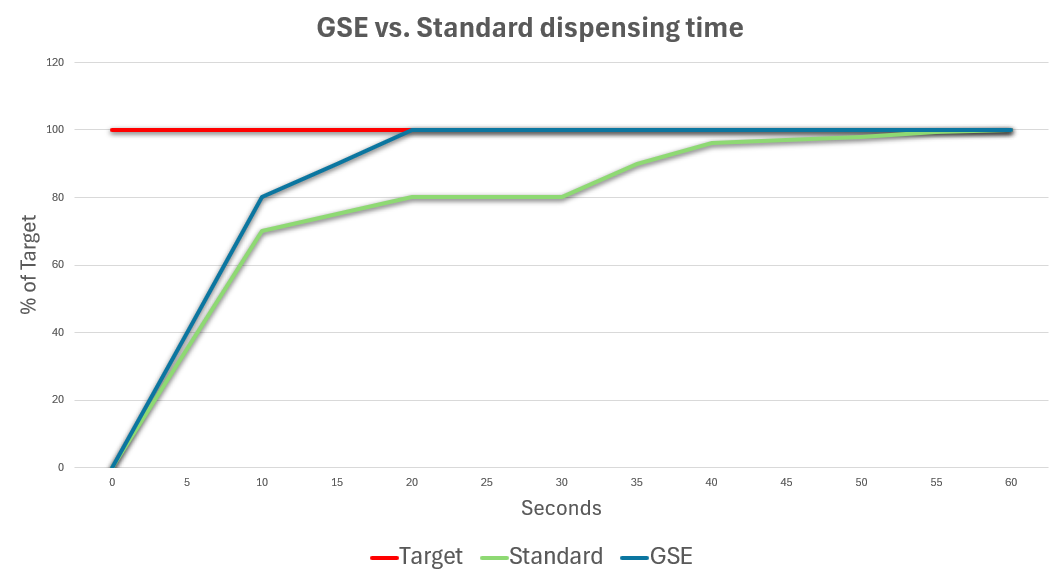

GSE’s valve control strategies and predictive algorithms further enhance performance. The smart self-learning system continuously learns from each dispensing operation, improving its ability to anticipate the stopping point and reduce overshoot. As a result, GSE dispensers achieve faster cycle times and higher precision compared to traditional dispensing systems. Their performance is illustrated in the graph below:

Conclusion

Dispensing technology is no longer just about mixing ink: it is about combining software intelligence, mechanical precision, and adaptive learning into a system that delivers consistent quality, higher efficiency, and responsiveness within the workflow. By uniting advanced software with carefully engineered hardware, modern dispensing machines turn a complex, variable process into a controlled and reliable part of the production workflow, empowering our clients to work smarter and faster, not harder.

Want to know more?

Sign up here to receive regular updates on this blog series. Also, contact our sales team for a consultation, on email info@gsedispensing.com or telephone +31 575 568 080.