Continuing our series on navigating ink-related food safety standards

We’re publishing dedicated blogs that explore each standard and explain how our ink management solutions can help you comply with them. See our previous blogs on housekeeping and cleaning, hazard analysis and risk management, record keeping, traceability and equipment maintenance.

In our InkConnection blogs, we’ve often discussed reducing the Eight Wastes of Lean – eliminating inefficiencies to improve productivity and sustainability. And with our software solutions for processing return inks, we help our customers prevent ink waste. In some cases, however, disposal of ink is the only option because it has expired or become contaminated, for example. In this blog, we’re focusing on how to dispose of ink in accordance with GFSI standards.

We’ll cover the waste handling requirements set by GFSI-recognized schemes (BRCGS, SQF, and FSSC 22000), discuss the critical role of ink disposal, and explain how our solutions can help you align your practices with the highest food safety standards.

Waste management requirements in the three food safety management schemes

The criteria for waste and waste disposal can be found in:

- Section 4.12 of the BRC Global Standard (BRCGS) for Packaging Materials

- Sections 2.4 of FSSC 22000 (Food Safety System Certification)

- Section 13.8 of Safe Quality Food (SQF).

Below, we summarize the requirements of these three schemes.

Waste handling procedures

Printers are expected to have documented programs for waste collection and disposal, ensuring that waste handling procedures minimize the risk of cross-contamination.

Waste containers and storage areas must be clearly marked, designed for easy cleaning, well-maintained, and emptied regularly.

Regular inspections and reviews are required to ensure ongoing compliance.

Ink waste

Fresh ink in inventory barrels may expire, while press-return inks can become contaminated or pass their expiry dates. Typically, waste inks are collected in designated containers and stored in a secured area. Since ink waste is classified as chemical waste, it must be disposed of by specialized third-party providers who ensure secure handling and maintain detailed records of the quantities processed.

GSE solutions to help managing ink waste

With the GSE Return ink management software, sorting press-return inks by expiry date and collecting expired inks becomes a straightforward task. With just one click, a return ink container can be removed from the warehouse, automatically labeled as “to be disposed,” and its weight recorded. Once the label is applied, the ink is transferred to the disposal area, where the waste is then registered.

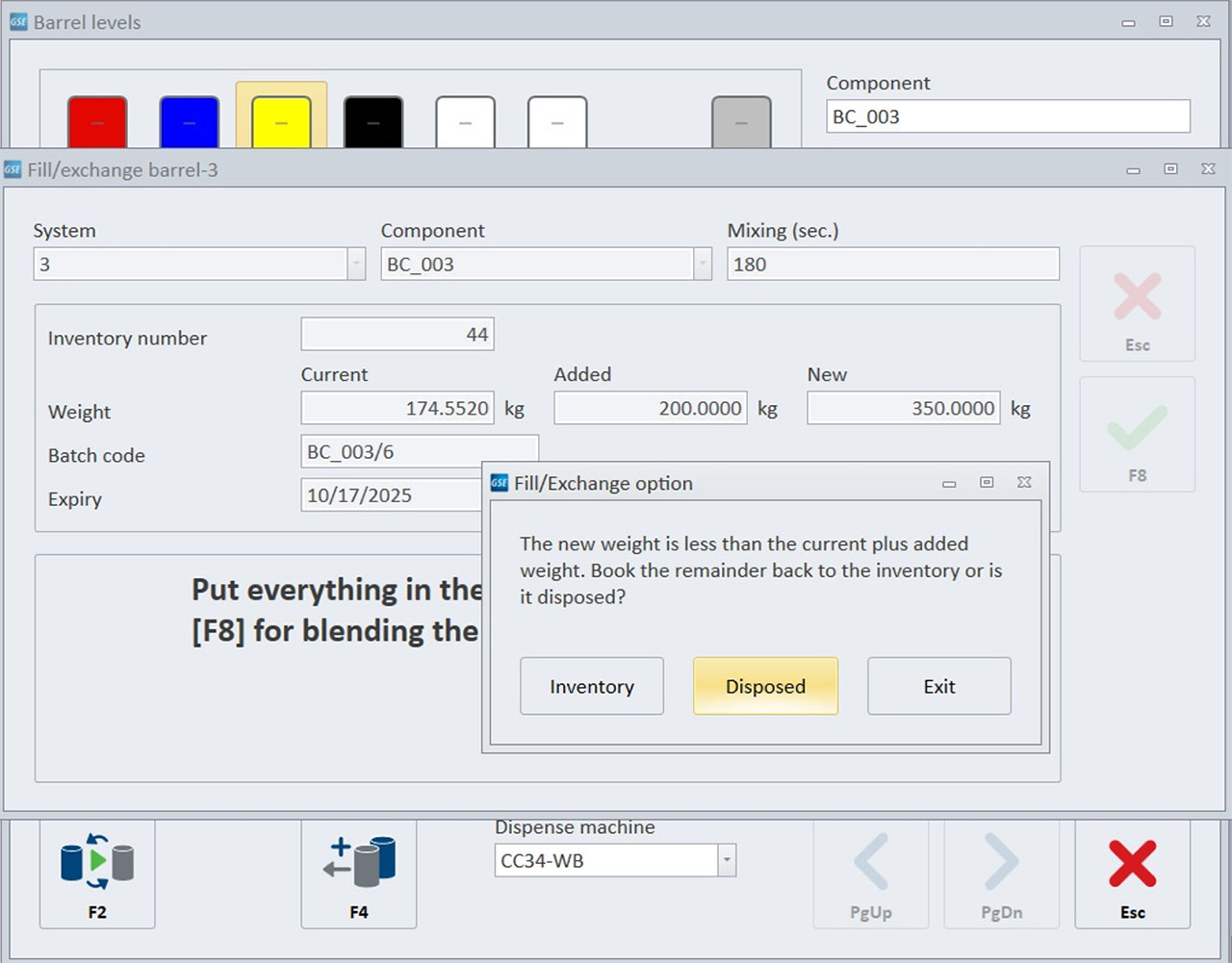

Additionally, the GSE Advanced logistics software module enables inventory barrels with base inks to be sorted by expiry date, ensuring that all expired inks are efficiently identified and disposed of. The software lets you choose whether to dispose or return remaining ink to the inventory when filling or changing barrels at the machine.

Recording disposed inks after refilling or replacing a barrel using GSE Ink manager

In the database, all disposed inks are recorded, enabling the generation of various reports if needed.

If buckets with waste inks are emptied into a collection container, these can optionally be cleaned using a GSE Indigo bucket washer.

How we support you on your compliance journey

Compliant ink waste management is crucial for both food safety and operational efficiency. By following GFSI standards and using GSE solutions, you can safely sort, label, and dispose of expired or contaminated inks.

Stay tuned for more insights on food safety standards and how GSE can support your compliance journey.

Further reading on the InkConnection blogsite

- Beat the Eight Wastes for competitive edge!

- Housekeeping and cleaning essentials for your ink room

- Advanced techniques for efficient return ink management

If you need guidance on meeting GFSI traceability requirements, please don’t hesitate to contact us at info@gsedispensing.com.